© 2024 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ TIJ Inkjet - Print Personalisation and Numbering

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The SV-360 finds its perfect use in terms of fully automatic numbering and coding on pre-printed individual

sheets and NCR form sets, event tickets, gift vouchers, certificates etc. but also on high-security documents

like bank drafts, cheques, schengen visa and other ID related documents.

Due to its modular construction, the machine can be extended by retrofitting with increasing demand with

further numbering and hologram heads as well as label dispensers, also at any later date. An optional paper

tractor system additionally allows the processing of continuous forms and sheet-fed on the same system.

Numbering and imprinting heads of the series Radus SU

In combination with the numbering heads of the SU series, numberings in e.g. Gothic, CMC 7, E13B and

OCR as well as barcode, signatures and logos can be printed.

A printing head change is possible within minutes.

● SU1

Whenever simple numbering is required, the SU1 numbering head, proven thousands of times in use, can

demonstrate its performance. With the extremely low printing costs, it is unrivalled in its field of application.

Oil-based stamping inks are used for printing on absorbent materials made from paper. Used in combination

with steel rotary numbering machines, the controllable pressure setting of the SU printing heads provides

easy crash numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the SU2 numbering head is an impressive direct development

of the tried-and-tested SU1. This allows the imprinting of high-quality Gothic and OCR numbering, as well

as barcode, in all types of document. Optionally, the numbering head SU2 is also available as Computerized

CRN variant. (Computer Random Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding using special carbon ribbons. The ink

on a carrier film is transferred cold, directly to the paper, using pressure from the numbering unit. The

numbering head processes carbon ribbons for OCR and MICR numbering, as well as black ribbons with

additional security features, such as UV fluorescence yellow / green and indelible red ink penetration - bleed

through. Replacing the rotary numbering machine with magnetic print blocks enables the imprinting of

signatures and logos.

Feeding Systems

Various feeder and delivery systems are available, tailored to the production volumes. A vacuum rotation

feeder unit is used for small to medium press runs, which pulls sheets in formats of up to 520mm x 650mm

from below. The magazine capacity is naturally limited in this case but the feeder can be refilled whilst the

machine is running. The processed sheets are delivered into a suitable jogger. The accurately stacked

sheets can be removed during operation for further finishing.

Autonomous times

Pile feeders and pile delivery systems can be used for large press runs and for long periods of autonomous

operation; these are equipped with electrically driven stacker platforms that can be raised and lowered,

each with a magazine capacity of 650 mm. Due to their maximum paper format of 520mm x 750mm, these

also support the classic B2 sheets. Like the system's upgrade facility, the pile feeder and pile delivery can

also be retrofitted at any time.

Operating process

After sheet separation with double-sheet inspection, the sheet is drawn to a zero line in an aligning station

and passed to the vakuum transport of the work station. Here, one or two SU heads can be used. The sheet

is moved under the numbering heads and stopped at the required position; numbering then takes place.

The operator selects whether one or both heads are used for numbering at the position. After numbering,

the sheet is moved to the next position. In this way, each sheet can be numbered in 25 freely-selectable

positions, e.g. for tickets, cheques or tax labels arrange d one above the other. The completed sheets are

passed to the stacker; during this time a new sheet arrives at the work station ready aligned in order to

guarantee continuous production.

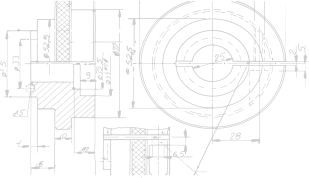

RADUS SV-360 / SU

Numbering and Coding System

SPECIFICATIONS

Functions / Features

Transport for individual sheets and single sticker (visa)

Additional transport for continuous forms (optional)

Rotary numbering maschines, standard and customized

CRN numbering machine for SU2 with Letterpress (optional)

Crash numbering for NCR form sets

Expandability with labeling and hologram application

Optional deep pile feeder and delivery - 650mm height

Basic Model SV-360 with SU Numbering Heads

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ touch

Transport system

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous

up to 33”

forms

Paper weight

70 - 500g/m² sheet-fed

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering machines of steel / opt. pre-inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and Logos

SU4

Print head for carbon ribbons, single and multi strike, optional with MICR,

UV fluorescence yellow / green and indelible red ink penetration - bleed through,

other ribbons on request

Print carrier

Rotary numbering machines of steel or part carrier

Fonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg (depending on configuration)

Performance

Sheet-fed up to 15.000 numberings/h per SU-head

Continuous forms up to 16.500 numberings/h per

SU-head

Sheet-Fed & Continuous Forms

- All Products Overview

- Hologram Polycarbonate

- Hologram Sheet-Fed

- Hologram Continious Forms

- UV-DOD Inkjet Personalisation

- TIJ Inkjet Print Personalisation

- RFID Personalization

- Numbering Sheet-Fed

- Numbering Continuous Forms

- Numbering Manual Handling

- Numbering Heads

- Numbering Ribbons

- Scratch Application

© 2024 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Bleed Through

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application Hot Stamping Polycarbonate

■ Hologram Applicator for Sheet-Fed - Paper

■ Hologram Applicator for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The SV-360 finds its perfect use in terms of fully automatic numbering

and coding on pre-printed individual sheets and NCR form sets, event

tickets, gift vouchers, certificates etc. but also on high-security

documents like bank drafts, cheques, schengen visa and other ID

related documents.

Due to its modular construction, the machine can be extended by

retrofitting with increasing demand with further numbering and hologram

heads as well as label dispensers, also at any later date. An optional

paper tractor system additionally allows the processing of continuous

forms and sheet-fed on the same system.

Numbering and imprinting heads of the series Radus SU

In combination with the numbering heads of the SU series, numberings

in e.g. Gothic, CMC 7, E13B and OCR as well as barcode, signatures

and logos can be printed.

A printing head change is possible within minutes.

● SU1

Whenever simple numbering is required, the SU1 numbering head,

proven thousands of times in use, can demonstrate its performance.

With the extremely low printing costs, it is unrivalled in its field of

application. Oil-based stamping inks are used for printing on absorbent

materials made from paper. Used in combination with steel rotary

numbering machines, the controllable pressure setting of the SU

printing heads provides easy crash numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the SU2 numbering head

is an impressive direct development of the tried-and-tested SU1. This

allows the imprinting of high-quality Gothic and OCR numbering, as well

as barcode, in all types of document. Optionally, the numbering head

SU2 is also available as Computerized CRN variant. (Computer

Random Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding

using special carbon ribbons. The ink on a carrier film is transferred

cold, directly to the paper, using pressure from the numbering unit. The

numbering head processes carbon ribbons for OCR and MICR

numbering, as well as black ribbons with additional security features,

such as UV fluorescence yellow / green and indelible red ink

penetration - bleed through. Replacing the rotary numbering machine

with magnetic print blocks enables the imprinting of signatures and

logos.

Feeding Systems

Various feeder and delivery systems are available, tailored to the

production volumes. A vacuum rotation feeder unit is used for small to

medium press runs, which pulls sheets in formats of up to 520mm x

650mm from below. The magazine capacity is naturally limited in this

case but the feeder can be refilled whilst the machine is running. The

processed sheets are delivered into a suitable jogger. The accurately

stacked sheets can be removed during operation for further finishing.

Autonomous times

Pile feeders and pile delivery systems can be used for large press runs

and for long periods of autonomous operation; these are equipped with

electrically driven stacker platforms that can be raised and lowered,

each with a magazine capacity of 650 mm. Due to their maximum paper

format of 520mm x 750mm, these also support the classic B2 sheets.

Like the system's upgrade facility, the pile feeder and pile delivery can

also be retrofitted at any time.

Operating process

After sheet separation with double-sheet inspection, the sheet is drawn

to a zero line in an aligning station and passed to the vakuum transport

of the work station. Here, one or two SU heads can be used. The sheet

is moved under the numbering heads and stopped at the required

position; numbering then takes place. The operator selects whether one

or both heads are used for numbering at the position. After numbering,

the sheet is moved to the next position. In this way, each sheet can be

numbered in 25 freely-selectable positions, e.g. for tickets, cheques or

tax labels arrange d one above the other. The completed sheets are

passed to the stacker; during this time a new sheet arrives at the work

station ready aligned in order to guarantee continuous production.

RADUS SV-360 / SU

Numbering and Coding

System

SPECIFICATIONS

Functions / Features

Transport for individual sheets and single sticker (visa)

Additional transport for continuous forms (optional)

Rotary numbering maschines, standard and customized

CRN numbering machine for SU2 with Letterpress (optional)

Crash numbering for NCR form sets

Expandability with labeling and hologram application

Optional deep pile feeder and delivery - 650mm height

Basic Model SV-360 with SU Numbering Heads

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ touch

Transport system

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous

up to 33”

forms

Paper weight

70 - 500g/m² sheet-fed

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering machines of steel / opt. pre-

inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and Logos

SU4

Print head for carbon ribbons, single and multi strike,

optional with MICR,

UV fluorescence yellow / green and indelible red ink

penetration - bleed through,

other ribbons on request

Print carrier

Rotary numbering machines of steel or part carrier

Fonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg (depending on configuration)

Performance

Sheet-fed up to 15.000 numberings/h per SU-head

Continuous forms up to 16.500 numberings/h per

SU-head

Sheet-Fed & Continuous Forms

© 2024 Arnold Herzig GmbH • Germany - All rights reserved

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine

The SV-360 finds its perfect use in terms of fully automatic numbering and coding on pre-

printed individual sheets and NCR form sets, event tickets, gift vouchers, certificates etc. but

also on high-security documents like bank drafts, cheques, schengen visa and other ID

related documents.

Due to its modular construction, the machine can be extended by retrofitting with increasing

demand with further numbering and hologram heads as well as label dispensers, also at any

later date. An optional paper tractor system additionally allows the processing of continuous

forms and sheet-fed on the same system.

Numbering and imprinting heads of the series Radus SU

In combination with the numbering heads of the SU series, numberings in e.g. Gothic, CMC

7, E13B and OCR as well as barcode, signatures and logos can be printed.

A printing head change is possible within minutes.

● SU1

Whenever simple numbering is required, the SU1 numbering head, proven thousands of

times in use, can demonstrate its performance. With the extremely low printing costs, it is

unrivalled in its field of application. Oil-based stamping inks are used for printing on

absorbent materials made from paper. Used in combination with steel rotary numbering

machines, the controllable pressure setting of the SU printing heads provides easy crash

numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the SU2 numbering head is an impressive

direct development of the tried-and-tested SU1. This allows the imprinting of high-quality

Gothic and OCR numbering, as well as barcode, in all types of document. Optionally, the

numbering head SU2 is also available as Computerized CRN variant. (Computer Random

Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding using special carbon

ribbons. The ink on a carrier film is transferred cold, directly to the paper, using pressure

from the numbering unit. The numbering head processes carbon ribbons for OCR and MICR

numbering, as well as black ribbons with additional security features, such as UV

fluorescence yellow / green and indelible red ink penetration - bleed through. Replacing the

rotary numbering machine with magnetic print blocks enables the imprinting of signatures

and logos.

Feeding Systems

Various feeder and delivery systems are available, tailored to the production volumes. A

vacuum rotation feeder unit is used for small to medium press runs, which pulls sheets in

formats of up to 520mm x 650mm from below. The magazine capacity is naturally limited in

this case but the feeder can be refilled whilst the machine is running. The processed sheets

are delivered into a suitable jogger. The accurately stacked sheets can be removed during

operation for further finishing.

Autonomous times

Pile feeders and pile delivery systems can be used for large press runs and for long periods

of autonomous operation; these are equipped with electrically driven stacker platforms that

can be raised and lowered, each with a magazine capacity of 650 mm. Due to their

maximum paper format of 520mm x 750mm, these also support the classic B2 sheets. Like

the system's upgrade facility, the pile feeder and pile delivery can also be retrofitted at any

time.

Operating process

After sheet separation with double-sheet inspection, the sheet is drawn to a zero line in an

aligning station and passed to the vakuum transport of the work station. Here, one or two

SU heads can be used. The sheet is moved under the numbering heads and stopped at the

required position; numbering then takes place. The operator selects whether one or both

heads are used for numbering at the position. After numbering, the sheet is moved to the

next position. In this way, each sheet can be numbered in 25 freely-selectable positions, e.g.

for tickets, cheques or tax labels arrange d one above the other. The completed sheets are

passed to the stacker; during this time a new sheet arrives at the work station ready aligned

in order to guarantee continuous production.

RADUS SV-360 / SU

Numbering and Coding System

SPECIFICATIONS

Functions / Features

Transport for individual sheets and single sticker (visa)

Additional transport for continuous forms (optional)

Rotary numbering maschines, standard and customized

CRN numbering machine for SU2 with Letterpress (optional)

Crash numbering for NCR form sets

Expandability with labeling and hologram application

Optional deep pile feeder and delivery - 650mm height

Basic Model SV-360 with SU Numbering Heads

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ touch

Transport system

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous

up to 33”

forms

Paper weight

70 - 500g/m² sheet-fed

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering machines of steel / opt. pre-inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and Logos

SU4

Print head for carbon ribbons, single and multi strike, optional with MICR,

UV fluorescence yellow / green and indelible red ink penetration - bleed through,

other ribbons on request

Print carrier

Rotary numbering machines of steel or part carrier

Fonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg (depending on configuration)

Performance

Sheet-fed up to 15.000 numberings/h per SU-head

Continuous forms up to 16.500 numberings/h per

SU-head

Sheet-Fed & Continuous Forms