© 2025 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ TIJ Inkjet - Print Personalisation and Numbering

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

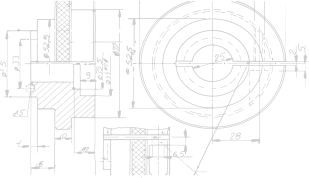

The SV-360 machine with high resolution UV-DOD

inkjet printing system finds its perfect use when it

comes to variable print personalization, serialization

and coding on single sheets and flat blanks made of

paper and cardboard.

UV-DOD Inkjet Printing System with 360dpi

Modular UV-DOD inkjet heads in combination with the latest LED UV-curing technology allow the high- resolution and accurate imprint of variable data such as texts, numbers, barcodes, 2D codes and graphics on a wide variety of formats from absorbent and non- absorbent substrates. Due to its modular construction, the machine can be extended with increasing demand up to four DOD inkjet heads. For this, modules with print widths of 72mm and 144mm are available. An optional paper tractor additionally allows the processing of continuous forms and individual sheets on the same system. Layout Editor / Raster Image Processor (RIP) The under Windows operating print control software R-DOD has an user-friendly layout editor and takes over the raster image processing (RIP) of all print data. Variable content such as texts, numbering and common 1D / 2D barcodes can simply be placed via drag & drop on the layout and connected directly to the desired database field. Verification and Control by Plug & Play For print data verification and quality control in the production process, the well proven R-CHECK camera system can be seamlessly integrated into the print controller. High-resolution CCD camera modules check in a few milliseconds each print for completeness, legibility and data integrity. The integrated control concept enables an intuitive handling, fast job changes and short set-up times. Feeding Systems Various feeder and delivery systems are available, tailored to the production volumes. A vacuum rotation feeder unit is used for small to medium press runs, which pulls sheets in formats of up to 520mm x 650mm from below. The magazine capacity is accordingly limited in this case but the feeder can be refilled whilst the machine is running. The processed sheets are delivered into a suitable jogger. The accurately stacked sheets can be removed during operation for further finishing. Autonomous Times Pile feeders and pile delivery systems can be used for large press runs and for long periods of autonomous operation; these are equipped with electrically driven stacker platforms that can be raised and lowered, each with a magazine capacity of 650 mm. Due to their maximum paper format of 520mm x 750mm, these also support the classic B2 sheets. Like the system's upgrade facility, the pile feeder and pile delivery can also be retrofitted at any time. Operating Process After sheet separation with double-sheet inspection, the sheet is drawn to a zero line in the aligning station and passed to the vacuum transport of the printing station. Fixed by the vacuum, the aligned sheet is printed at a constant speed here. After printing, the direct curing by an LED UV and subsequent camera check is made. The completed sheets are passed to the stacker; during this time a new sheet arrives at the print station ready aligned in order to guarantee continuous production.

SPECIFICATIONS

Functions / Features

• Feeder and transport for processing individual sheets

• Basic machine from 1 x UV-DOD Inkjet printing system

• Serialization, variable data print, e.g. text, numbers, barcodes

• High-resolution print systems from 72mm to 144mm

• Ozone free LED UV-curing

• Data verification & controll by camera system (optional)

• Optional deep pile feeder and delivery - 650mm height

• Additional transport for continuous forms (optional)

Basic Machine SV-360 with UV-DOD Inkjet

Controlling

Microprocessor

Operation

Fully automatic

Controll desk

7“ Touch display

PC Controll

WindowsTM

Transport System

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous forms

up to 33”

Paper weight

70 - 400g/m² sheet-fed (up to 1.0mm)

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Print System

1 to 4 x Inkjet, Piezo DOD (Drop-On-Demand)

Print width

72mm, 144mm

Resolution

360dpi

Print speed

30 and 60/min

Standard ink

Black (UV)

Curing

LED UV

Layout Editor

Radus DOD layout designer incl. RIP

Database-based variable data printing of numbers

and texts (Type-True Fonts), graphics, 1D/2D

barcodes, datamatrix, QR

Verification

Radus CHECK

1 to 4 CCD-Cameras with adjustable aperture and

focus, individually programmable check fields for

OCR, barcode and measurement

OCR/OCV

teachable fonts

Barcode

1D/2D barcodes, datamatrix, QR

Illumination

LED lighting

Connections

Electrical

1/3 phase 50/60Hz, 2 - 4kW

Connection

depending on configuration

Dimensions from

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg, depending on configuration

Performance

• Single sheets up to 60m/min

Sheet-Fed & Continuous Forms

RADUS SV-360

UV-DOD Inkjet Variable

Data Printing System

- All Products Overview

- Hologram Polycarbonate

- Hologram Sheet-Fed

- Hologram Continious Forms

- UV-DOD Inkjet Personalisation

- TIJ Inkjet Print Personalisation

- RFID Personalization

- Numbering Sheet-Fed

- Numbering Continuous Forms

- Numbering Manual Handling

- Numbering Trading Cards

- Numbering Heads

- Numbering Ribbons

- Scratch Application

© 2025 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Bleed Through

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application Hot Stamping Polycarbonate

■ Hologram Applicator for Sheet-Fed - Paper

■ Hologram Applicator for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The SV-360 machine with high resolution UV-DOD inkjet printing system

finds its perfect use when it comes to variable print personalization,

serialization and coding on single sheets and flat blanks made of paper

and cardboard.

UV-DOD Inkjet Printing System with 360dpi

Modular UV-DOD inkjet heads in combination with the latest LED UV- curing technology allow the high-resolution and accurate imprint of variable data such as texts, numbers, barcodes, 2D codes and graphics on a wide variety of formats from absorbent and non-absorbent substrates. Due to its modular construction, the machine can be extended with increasing demand up to four DOD inkjet heads. For this, modules with print widths of 72mm and 144mm are available. An optional paper tractor additionally allows the processing of continuous forms and individual sheets on the same system. Layout Editor / Raster Image Processor (RIP) The under Windows operating print control software R-DOD has an user- friendly layout editor and takes over the raster image processing (RIP) of all print data. Variable content such as texts, numbering and common 1D / 2D barcodes can simply be placed via drag & drop on the layout and connected directly to the desired database field. Verification and Control by Plug & Play For print data verification and quality control in the production process, the well proven R-CHECK camera system can be seamlessly integrated into the print controller. High-resolution CCD camera modules check in a few milliseconds each print for completeness, legibility and data integrity. The integrated control concept enables an intuitive handling, fast job changes and short set-up times. Feeding Systems Various feeder and delivery systems are available, tailored to the production volumes. A vacuum rotation feeder unit is used for small to medium press runs, which pulls sheets in formats of up to 520mm x 650mm from below. The magazine capacity is accordingly limited in this case but the feeder can be refilled whilst the machine is running. The processed sheets are delivered into a suitable jogger. The accurately stacked sheets can be removed during operation for further finishing. Autonomous Times Pile feeders and pile delivery systems can be used for large press runs and for long periods of autonomous operation; these are equipped with electrically driven stacker platforms that can be raised and lowered, each with a magazine capacity of 650 mm. Due to their maximum paper format of 520mm x 750mm, these also support the classic B2 sheets. Like the system's upgrade facility, the pile feeder and pile delivery can also be retrofitted at any time. Operating Process After sheet separation with double-sheet inspection, the sheet is drawn to a zero line in the aligning station and passed to the vacuum transport of the printing station. Fixed by the vacuum, the aligned sheet is printed at a constant speed here. After printing, the direct curing by an LED UV and subsequent camera check is made. The completed sheets are passed to the stacker; during this time a new sheet arrives at the print station ready aligned in order to guarantee continuous production.

SPECIFICATIONS

Functions / Features

• Feeder and transport for processing individual sheets

• Basic machine from 1 x UV-DOD Inkjet printing system

• Serialization, variable data print, e.g. text, numbers, barcodes

• High-resolution print systems from 72mm to 144mm

• Ozone free LED UV-curing

• Data verification & controll by camera system (optional)

• Optional deep pile feeder and delivery - 650mm height

• Additional transport for continuous forms (optional)

Basic Machine SV-360 with UV-DOD Inkjet

Controlling

Microprocessor

Operation

Fully automatic

Controll desk

7“ Touch display

PC Controll

WindowsTM

Transport System

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous forms

up to 33”

Paper weight

70 - 400g/m² sheet-fed (up to 1.0mm)

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Print System

1 to 4 x Inkjet, Piezo DOD (Drop-On-Demand)

Print width

72mm, 144mm

Resolution

360dpi

Print speed

30 and 60/min

Standard ink

Black (UV)

Curing

LED UV

Layout Editor

Radus DOD layout designer incl. RIP

Database-based variable data printing of numbers

and texts (Type-True Fonts), graphics, 1D/2D

barcodes, datamatrix, QR

Verification

Radus CHECK

1 to 4 CCD-Cameras with adjustable aperture and

focus, individually programmable check fields for

OCR, barcode and measurement

OCR/OCV

teachable fonts

Barcode

1D/2D barcodes, datamatrix, QR

Illumination

LED lighting

Connections

Electrical

1/3 phase 50/60Hz, 2 - 4kW

Connection

depending on configuration

Dimensions from

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg, depending on configuration

Performance

• Single sheets up to 60m/min

Sheet-Fed & Continuous Forms

RADUS SV-360

UV-DOD Inkjet Variable

Data Printing System

- Home

- Security Printing

- RFID Technology

- Product Overview

- Hologram Polycarbonate

- Hologram Sheet-Fed

- Hologram Continuous

- Numbering Sheet-Fed

- RFID Personalisation

- Inkjet Personalisation

- Numbering Continuous

- Numbering Cards

- Numbering Manual

- Numbering Heads

- Numbering Ribbons (Carbon)

- Company

- Imprint

- Contact

© 2025 Arnold Herzig GmbH • Germany - All rights reserved

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The SV-360 machine with high

resolution UV-DOD inkjet printing

system finds its perfect use when it

comes to variable print

personalization, serialization and

coding on single sheets and flat

blanks made of paper and cardboard.

UV-DOD Inkjet Printing System

with 360dpi

Modular UV-DOD inkjet heads in combination with the latest LED UV- curing technology allow the high- resolution and accurate imprint of variable data such as texts, numbers, barcodes, 2D codes and graphics on a wide variety of formats from absorbent and non-absorbent substrates. Due to its modular construction, the machine can be extended with increasing demand up to four DOD inkjet heads. For this, modules with print widths of 72mm and 144mm are available. An optional paper tractor additionally allows the processing of continuous forms and individual sheets on the same system. Layout Editor / Raster Image Processor (RIP) The under Windows operating print control software R-DOD has an user-friendly layout editor and takes over the raster image processing (RIP) of all print data. Variable content such as texts, numbering and common 1D / 2D barcodes can simply be placed via drag & drop on the layout and connected directly to the desired database field. Verification and Control by Plug & Play For print data verification and quality control in the production process, the well proven R- CHECK camera system can be seamlessly integrated into the print controller. High-resolution CCD camera modules check in a few milliseconds each print for completeness, legibility and data integrity. The integrated control concept enables an intuitive handling, fast job changes and short set-up times. Feeding Systems Various feeder and delivery systems are available, tailored to the production volumes. A vacuum rotation feeder unit is used for small to medium press runs, which pulls sheets in formats of up to 520mm x 650mm from below. The magazine capacity is accordingly limited in this case but the feeder can be refilled whilst the machine is running. The processed sheets are delivered into a suitable jogger. The accurately stacked sheets can be removed during operation for further finishing. Autonomous Times Pile feeders and pile delivery systems can be used for large press runs and for long periods of autonomous operation; these are equipped with electrically driven stacker platforms that can be raised and lowered, each with a magazine capacity of 650 mm. Due to their maximum paper format of 520mm x 750mm, these also support the classic B2 sheets. Like the system's upgrade facility, the pile feeder and pile delivery can also be retrofitted at any time. Operating Process After sheet separation with double-sheet inspection, the sheet is drawn to a zero line in the aligning station and passed to the vacuum transport of the printing station. Fixed by the vacuum, the aligned sheet is printed at a constant speed here. After printing, the direct curing by an LED UV and subsequent camera check is made. The completed sheets are passed to the stacker; during this time a new sheet arrives at the print station ready aligned in order to guarantee continuous production.

SPECIFICATIONS

Functions / Features

• Feeder and transport for processing individual sheets

• Basic machine from 1 x UV-DOD Inkjet printing system

• Serialization, variable data print, e.g. text, numbers, barcodes

• High-resolution print systems from 72mm to 144mm

• Ozone free LED UV-curing

• Data verification & controll by camera system (optional)

• Optional deep pile feeder and delivery - 650mm height

• Additional transport for continuous forms (optional)

Basic Machine SV-360 with UV-DOD Inkjet

Controlling

Microprocessor

Operation

Fully automatic

Controll desk

7“ Touch display

PC Controll

WindowsTM

Transport System

Form width

Sheet-fed up to 520mm

Continuous forms up to 550mm incl.

sprocket holes

Form length

Sheet-fed up to 750mm with pile feeder

Continuous forms

up to 33”

Paper weight

70 - 400g/m² sheet-fed (up to 1.0mm)

40 - 200g/m² continuous forms

max. 400g/m² continuous form sets

Print System

1 to 4 x Inkjet, Piezo DOD (Drop-On-Demand)

Print width

72mm, 144mm

Resolution

360dpi

Print speed

30 and 60/min

Standard ink

Black (UV)

Curing

LED UV

Layout Editor

Radus DOD layout designer incl. RIP

Database-based variable data printing of numbers

and texts (Type-True Fonts), graphics, 1D/2D

barcodes, datamatrix, QR

Verification

Radus CHECK

1 to 4 CCD-Cameras with adjustable aperture and

focus, individually programmable check fields for

OCR, barcode and measurement

OCR/OCV

teachable fonts

Barcode

1D/2D barcodes, datamatrix, QR

Illumination

LED lighting

Connections

Electrical

1/3 phase 50/60Hz, 2 - 4kW

Connection

depending on configuration

Dimensions from

Length 2700mm x depth 800mm x height 1500mm

Weight

approx. 550kg, depending on configuration

Performance

• Single sheets up to 60m/min

Sheet-Fed & Continuous Forms

RADUS SV-360

UV-DOD Inkjet Variable

Data Printing System

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine